Medical Devices

A certificate of compliance with ISO-13485 (Medical Devices – Quality Management Systems – Requirements... View more

Use of ISO 10993: Biological Evaluation of Medical Devices

-

Use of ISO 10993: Biological Evaluation of Medical Devices

The ISO 10993 set entails a series of standards for evaluating the biocompatibility of medical devices. These documents were preceded by the Tripartite agreement and is a part of the international harmonisation of the safe use evaluation of medical devices. Medical devices that come into contact with the human body are required by the regulatory authorities to be tested on possible interactions and potential unwanted side effects. Therefore, medical devices are assigned to different categories dependent on the kind of contact and the contact time to the human body.

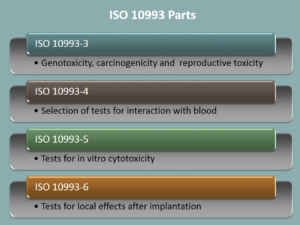

Tests According to ISO 10993 Parts

The purpose of ISO 10993 guidance is to provide further clarification and updated information on the use of International Standard ISO 10993-1, “Biological evaluation of medical devices – Part 1: Evaluation and testing within a risk management process” to support applications to FDA.

12 ISO 10993 STANDARDS

- 10993-1: “Guidance on Selection of Tests.”

- 10993-2: “Animal Welfare Requirements.”

- 10993-3: “Tests for Genotoxicity, Carcinogenicity, and Reproductive Toxicity.”

- 10993-4: “Selection of Tests for Interactions with Blood.”

- 10993-5: “Tests for Cytotoxicity—In Vitro Methods.”

- 10993-6: “Tests for Local Effects after Implantation.”

- 10993-7: “Ethylene Oxide Sterilization Residuals.”

- 10993-8: No title assigned.

- 10993-9: “Degradation of Materials Related to Biological Testing.”

- 10993-10: “Tests for Irritation and Sensitization.”

- 10993-11: “Tests for Systemic Toxicity.”

- 10993-12: “Sample Preparation and Reference Materials.”

The fundamental principles of toxicity evaluation expressed in ISO 10993-1 (and in the Tripartite Guidance) provide excellent guidelines for considering the safety of medical devices. These seven principles can be summarized as follows:

1. Materials should be characterized to provide an understanding of formulation, potential impurities, and extractables, and to provide the basis for specifications.

2. Leachable chemicals and degradation products should be considered in evaluating the toxicology of a device.

3. The availability of chemical extractables and degradation products to the patient when exposed to the device should be considered in designing testing programs.

4. Testing should be conducted according to good laboratory practices and evaluated by competent, informed persons.

5. Full experimental data should be made available to reviewing authorities.

6. Changes in the composition of materials, manufacturing practices, or intended use of the device should be evaluated with respect to possible changes in toxicological effects to patients.

7. All relevant data, including information from nonclinical sources, clinical studies, and postmarket experiences, should be taken into account when evaluating a device.

What are the Requirements for regulatory approval for medical devices?

The medical device, when used properly, may not expose the patient, user, or third party to unnecessary risks. The burden to ensure safety lies with the manufacturer or their representative. As a consequence, medical devices have to be tested with respect to their biocompatibility. This is the case for new products, as well as existing products which have undergone modification.

Sorry, there were no replies found.